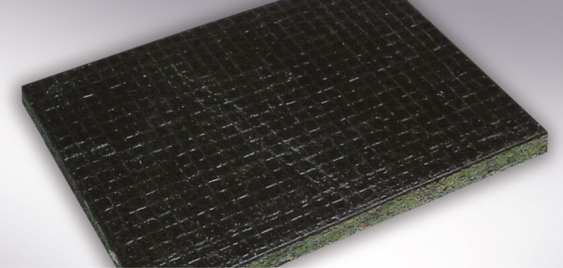

Alfakel M4000

General properties

| Front side: | black |

| Weight: | 6,5 Kg/mq |

| Thickness: | 23/25 mm |

| Temperature range: | –10 ÷ +80 °C |

| Heat resistance: | 0.5÷1.5 mq h °C/kcal |

| Vibrations resistance: | |

| – Tensile strength: | good |

| – Shear strength: | medium |

| Gasoline and oil resistance: | scarce for unprotected surfaces |

| Humidity resistance: | good |

Acoustic properties

The Alfakel M sound insulating panels are extremely valid in the range of high and medium frequencies. Generally, the simple “sandwich” elements are sufficient to achieve the insulation needed, except in rare situations requiring high levels of insulation against airborne noise. By modifying the thickness of the porous layer and the weight of the heavy layer it is possible, within to a certain extent, to adjust the insulation curve to the spectrum of the noise source for the specific frequencies.

In general, increasing the thickness of the porous layer and the weight of the heavy layer will lead the curve towards low frequencies.

Figure 1 shows the range of sound insulating power of the most typical “sandwich” Alfakel M.

The range represents the difference ∆ R between the sound insulation of a 1 mm. sheet metal treated with one Alfakel M “sandwich” and one untreated sheet metal taking in consideration four samples.

“Septum” 5÷6 Kg/sq. m (3÷4 mm)

“Porous” 1.200 g. /sq. m (20 mm)

Fig. 1:

Alfakel simple “sandwich”.

Sound insulation range.

“Septum” 5÷6 Kg/sq. m (3÷4 mm)

“Porous” 1.200 g./sq. m (20 mm)

Fig. 2:

Alfakel double “sandwich”.

Sound insulation range.

More benefits

- Fit well to the shape of the substrate.

- Do not require safety protection of the installation team.

Installation

Alfakel M damping tiles can be glued to the surfaces to be treated for sound insulation against airborne noises or they can be applied using other techniques (such as staples, nails, metal clips, etc.).

If the “sandwich” tiles are used without the Alfakel M damping product, the porous side of the “sandwich” needs to be applied directly onto the surface to be treated, so that the “Septum” side be on the visible face. When the “sandwich” tiles are used with the Alfakel M damper, they need to be placed in direct contact with the surface to be treated.

Special Applications

In these applications the heavy side is exposed to thermal heat or solvents such as gasoline, oil, etc.